| Transmitter Type |

Pointer Display; Pointer with zero returning; Pointer display with Output; LCD |

| Medium |

Fuel Oil; Petroleum; Petroleum Products; Vegetable Oil; Food; Chemical |

|

Accuracy |

±0.2%; ±0.5% |

|

Nominal Diamete |

DN8~DN200 mm |

| Nominal Pressure | PN1.6~6.3MPa |

| Medium Temperature | -10 °C~280 °C |

| Medium Viscosity | 2~3000mPa•s |

|

Power Supply |

12V DC; 24V DC |

|

Output Signal |

Pulse; 4~20mA.DC; RS485 |

|

Display |

Accumulative Flow, Single Measurement(Mechanical Dial); Remote transmission of total and instantaneous flow |

|

Explosion Proof |

Flame-proof Type, ExdIIBT4 |

|

Ambient Temperature |

-20~55°C |

|

Sensor Material: |

Cast Iron; Cast Steel; Stainless Steel |

|

Sensor Connection |

Flange, Screw, Sanitary Tri-clamp |

Cast Iron type (A), Cast Steel type (E), Stainless Steel type (B)

,-Cast-Steel-type-(E),-Stainless-Steel-type-(B).jpg)

High temperature Cast Iron (TA), Cast Steel type (TE), Stainless Steel type (TB)

,-Cast-Steel-type-(TE),-Stainless-Steel-type-(TB).jpg)

High viscosity Cast Iron (NA), Cast Steel type (NE)

,-Cast-Steel-type-(NE).jpg)

| QTLC | xxx | x | x | x | x | x | x | x | x | x | x | x |

|

Size (mm) |

DN8~DN200mm (1/4”~4”) |

|||||||||||

|

Media viscosity |

2~200 mPa·s |

D | ||||||||||

| 200~1000 mPa·s | E | |||||||||||

| 1000~2000 mPa·s | F | |||||||||||

| 3000~10000 mPa·s | H | |||||||||||

|

Accuracy |

±0.5% (Standard) | 5 | ||||||||||

|

±0.2% |

2 | |||||||||||

|

Body material |

Cast iron |

CI | ||||||||||

| Cast steel | CS | |||||||||||

| SS304 | SS | |||||||||||

|

Media Temperature |

20℃~+100℃ (Standard ) |

L | ||||||||||

| +100℃~+250℃ | H | |||||||||||

| Display | Pointer + Zero return | P | ||||||||||

| LCD + Zero return | L | |||||||||||

| Power Supply | Mechanical type | M | ||||||||||

|

24VDC |

2 | |||||||||||

| 12VDC | 1 | |||||||||||

| Output | No | N | ||||||||||

|

Pulse |

Y | |||||||||||

| 4-20mA | 4 | |||||||||||

| Communication | No | N | ||||||||||

|

RS485 |

R | |||||||||||

| HART | H | |||||||||||

|

Connection |

Flange (DN8~DN200 |

DIN: PN10, PN16, PN25, PN40 | D** | |||||||||

|

ANSI:150#, 300#, 400#, 600 |

A** | |||||||||||

| JIS:10K, 20K, 30K, 40K | J** | |||||||||||

|

Tri-clamp (DN8~DN80) |

C | |||||||||||

| Thread (DN8~DN150) | T | |||||||||||

| Ex-proof |

With |

N | ||||||||||

| Without | E | |||||||||||

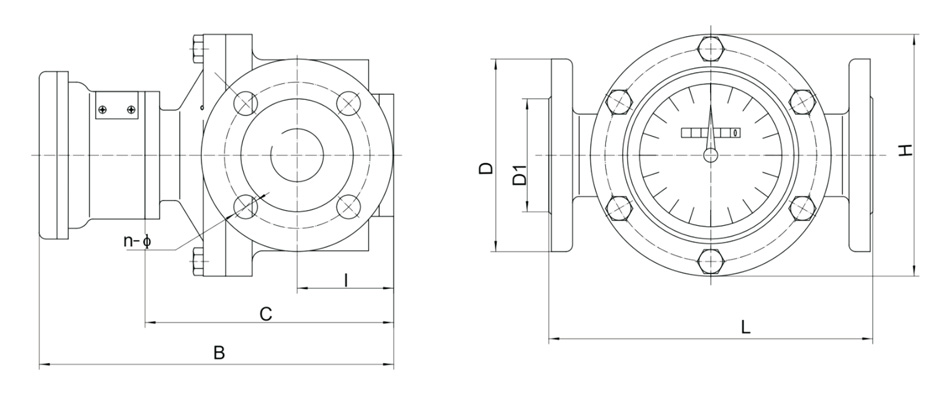

| DN | L | H | A | B | D | D1 | N | Φ |

| 10 | 150 | 100 | 165 | 210 | 90 | 60 | 4 | 14 |

| 15 | 170 | 118 | 172 | 225 | 95 | 65 | 4 | 14 |

| 20 | 200 | 150 | 225 | 238 | 105 | 75 | 4 | 14 |

| 25 | 260 | 180 | 232 | 246 | 115 | 85 | 4 | 14 |

| 40 | 245 | 180 | 249 | 271 | 145 | 110 | 4 | 18 |

| 50 | 340 | 250 | 230 | 372 | 160 | 125 | 4 | 18 |

| 65 | 420 | 325 | 270 | 386 | 180 | 145 | 4 | 18 |

| 80 | 420 | 325 | 315 | 433 | 195 | 160 | 8 | 18 |

| 100 | 515 | 481 | 370 | 458 | 215 | 180 | 8 | 18 |

| 150 | 540 | 515 | 347 | 557 | 280 | 240 | 8 | 23 |

| 200 | 650 | 650 | 476 | 720 | 335 | 295 | 12 | 23 |

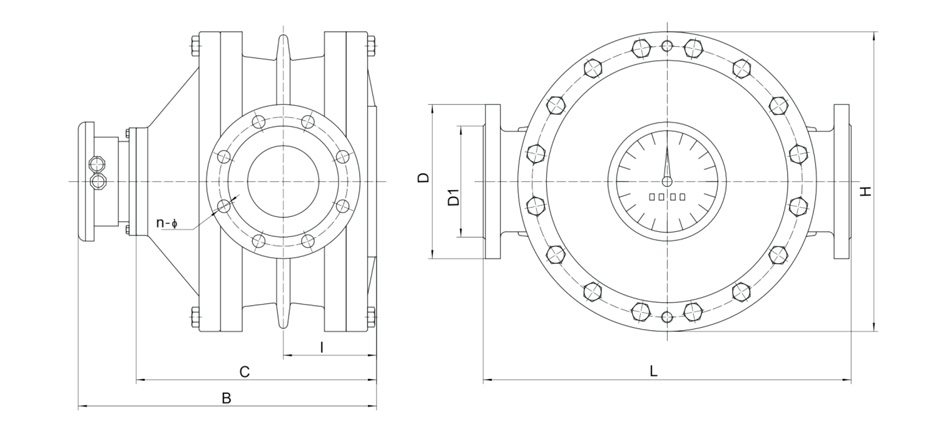

| DN | L | H | B | A | D | D1 | N | b |

| 15 | 200 | 138 | 232 | 180 | 105 | 75 | 4 | 14 |

| 20 | 250 | 164 | 220 | 160 | 125 | 9o | 4 | 18 |

| 25 | 300 | 202 | 252 | 185 | 135 | 100 | 4 | 18 |

| 40 | 300 | 202 | 293 | 208 | 165 | 125 | 4 | 23 |

| 50 | 384 | 262 | 394 | 312 | 175 | 135 | 4 | 23 |

| 80 | 450 | 337 | 452 | 332 | 210 | 170 | 8 | 23 |

| 100 | 555 | 442 | 478 | 310 | 250 | 200 | 8 | 25 |

| 150 | 540 | 510 | 557 | 347 | 300 | 250 | 8 | 26 |

| 200 | 650 | 650 | 720 | 476 | 36 | 310 | 12 | 26 |

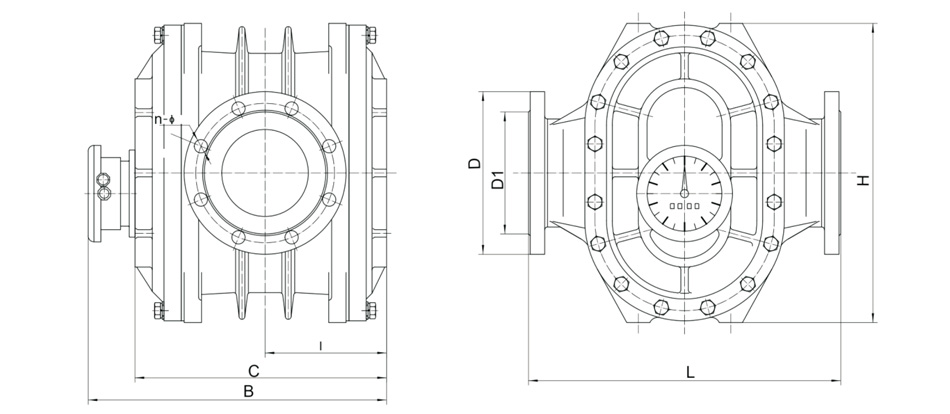

| DN | L | H | B | A | D | D1 | N | db |

| 15 | 208 | 120 | 228 | 172 | 95 | 65 | 4 | 14 |

| 20 | 236 | 150 | 238 | 225 | 105 | 75 | 4 | 14 |

| 25 | 287 | 195 | 246 | 232 | 115 | 85 | 4 | 14 |

| 40 | 265 | 178 | 349 | 265 | 145 | 110 | 4 | 18 |

| 50 | 265 | 178 | 349 | 265 | 160 | 125 | 4 | 18 |

| 65 | 365 | 260 | 436 | 319 | 180 | 145 | 4 | 18 |

| 8o | 420 | 305 | 459 | 324 | 200 | 160 | 8 | 18 |

| 100 | 515 | 400 | 554 | 373 | 220 | 180 | 18 | |

| 150 | 540 | 515 | 607 | 397 | 280 | 240 | 8 | 23 |